The escapement is a mechanical element of a clock or watch that converts raw energy into controlled impulses that consistently (and accurately) move the hands. The escapement works with a regulating element, either a pendulum in a large clock or balance wheel in a watch, which are themselves powered by a mainspring or gravity via hanging weights. The mechanical escapement was invented in the 13th century, although water-driven escapements go back even further to the Tang dynasty in China that ended in 907 AD. So, clocks existed even before the familiar clock towers that we generally associate with the dawn of timekeeping. The difference, however, is that clock towers were fully mechanical and independent of a water source.

Verge Escapement

Medieval clock towers used the original mechanical escapements known as verge escapements. These are crude by today’s standards with loose tolerances, no jewels and bulky designs. In Europe during the 14th century, mechanical clocks replaced water driven counterparts and were not only more accurate, but could be constructed anywhere. A controlled, repetitive oscillation in the form of a foliot (and later pendulums) engaged with the new verge escapement and timekeeping as we know it was born. A century earlier, the verge escapement was used for bell-ringing devices that could audibly signal an hour, so it was around even before proper clocks.

The name comes from Latin virga, meaning rod, and the origins of this first escapement are unknown. Large clock towers were confined to cathedrals or town centers with massive clockworks using the verge escapement and foliot, the latter being a horizontal bar with weights at either end that oscillated. Adjusting the weights sped up or slowed the oscillations, which is how accuracy was tweaked. The familiar pendulum replaced the foliot in the mid-1600s and accuracy increased from sometimes hours a day to just minutes. Pocket watches had a similar breakthrough in this century with the new balance wheel and hairspring, and modern timekeeping truly began. Significant improvements, however, lay ahead.

How Does a Verge Escapement Work?

The verge escapement has two main parts, the escape wheel and verge. The wheel looks like a crown with angle teeth like a saw blade, while the verge is a rod with two angled metal plates that engage the teeth at either end, one at a time. This creates the tick tock sound and slowly drives the hands. Powering the escapement is either a weighted foliot or pendulum in large clocks, or mainspring in pocket watches and many small clocks. The two metal plates (or pallets) on the verge, driven by the foliot, pendulum or mainspring, move in opposite directions and create impulses with the escape wheel by locking and unlocking with the teeth. This is a bit of a simplification, but that’s the gist of it.

The crown-like verge escape wheel must have an odd number of teeth and their angles ranged from 90 degrees to 115 degrees, depending on the design and advancements. For example, French clockmakers used the more extreme 115-degree teeth for increased accuracy, but this compromised the design as the verge had to be very close to the wheel, necessitating modified pendulums. By the late 1600s, the finest clocks were accurate to seconds per day, which is acceptable even by today’s standards. However, verge escapements were very susceptible to wear and any change in energy like an unwinding mainspring significantly decreased accuracy.

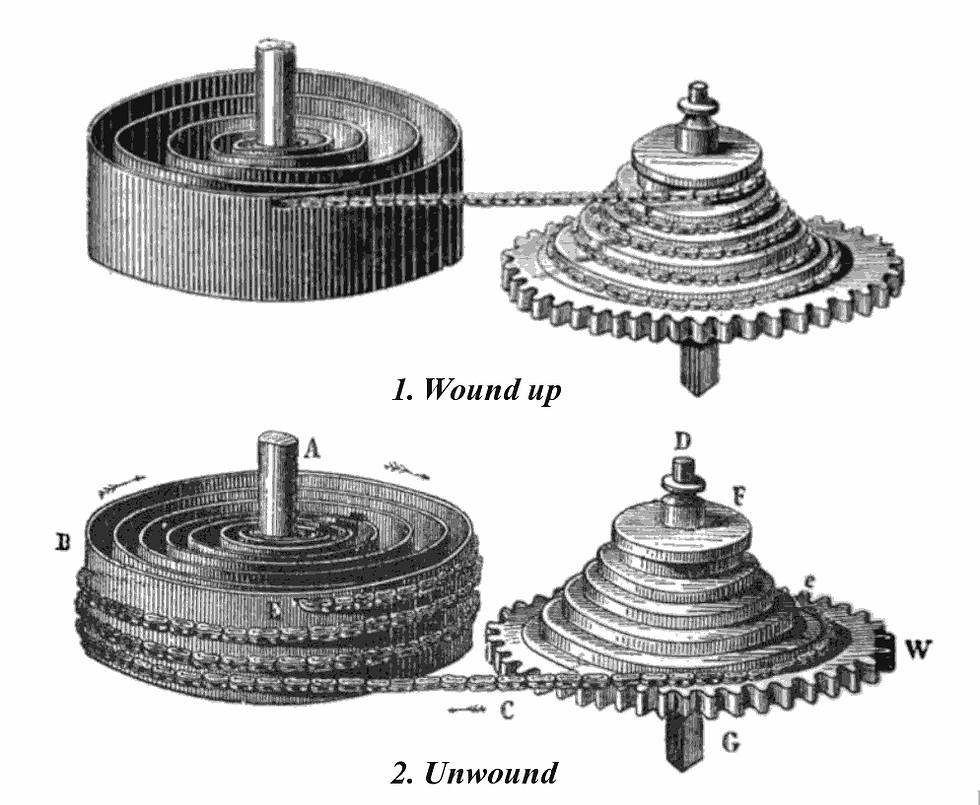

Enter the Fusee

Later verge clocks were generally accurate with pendulums that provided consistent power, but verge pocket watches required something to compensate for mainsprings that lost power when unwinding. The fusee was the answer for most spring-driven timekeepers, either watches or small clocks. It was a cone-shaped wheel with a chain or cord that connected directly to the mainspring, compensating for the change in power (not unlike changing gears on a bicycle when your legs tire). As the mainspring unwound, it pulled on wider and wider parts of the fusee as it unwound, adding additional turning force from the weaker spring. A ratcheting mechanism prevented the fusee from rotating backwards and its shape almost perfectly matched the power fluctuations. This helped solve the verge escapement’s shortcomings for centuries.

Anchor Escapement

While the verge escapement was standard for many pocket watches into the 19th century, the anchor escapement became favored for clocks as early as the late 17th century. The escape wheel and pallet fork became vertical, streamlining the design and allowing for reduced swing angles of the pendulum. This greatly increased accuracy and reliability, and led to the addition of a minute hand. Before the anchor escapement, most clocks just had an hour hand as accuracy wasn’t reliable enough for minutes.

The flat anchor escape wheel had long, backward leaning teeth that engaged with the anchor above (pallet fork), which moved back and forth via the pendulum to lock and unlock from the teeth, one at a time. It wasn’t perfect and still had friction and wear issues, but was a big step forward from the verge escapement. An improved version, known as the deadbeat escapement, had curved ends on the anchor that helped prevent recoil and a slight backward push of the escape wheel as the teeth engaged. This type is still used today in pendulum clocks.

Cylinder Escapement

Clocks were generally established at this point with the anchor escapement and refined variants, but the next major advancement for pocket watches was the cylinder escapement. It was invented in 1695, but reworked into a finished product in 1726 by English clockmaker George Graham. This was the escapement that often replaced the verge type in pocket watches and was much thinner for more streamlined cases. Unfortunately, it wore out quickly, so the English somewhat abandoned the new design, but French watchmakers all but solved the problem. By making the cylinder and escape wheel from hardened steel, the movement was not only more robust, but cheap to produce.

It's called the cylinder escapement as the traditional pallet fork was replaced by a cylinder with cutouts to engage the escape wheel teeth. Although cheaper and relatively accurate, the escape wheel made longer contact with the cylinder, so there was increased friction and consequently wear, and more frequent maintenance was required. It was a major improvement over the clunky verge escapement, but more work was needed.

Lever Escapement

Thomas Mudge invented the lever escapement in the 1750s and it’s among the most important developments in watchmaking. It’s a detached-type escapement, where the balance wheel swings freely for most of the oscillation except for a short impulse period where the pallet fork engages the escape wheel teeth (reducing friction and wear). It kind of resembles an anchor escapement in how the pallet fork works with the escape wheel below, but the shape of the teeth and pallets were optimized to virtually eliminate recoil and reduce friction. It can also restart if disturbed, which is important as older escapements could stop if knocked or otherwise jarred enough to interrupt the balance wheel. A lever escapement will automatically start again and rarely stops like the others. It’s been the escapement used in virtually all mechanical watches since the start of the 20th century and is accurate, reliable and robust.

This isn’t an exhaustive list of escapements as many others exist, but it covers the major and most common types.

Horage Escapements

If you're new to watchmaking and/or Horage, here are a few things about us in relation to escapements. Most Swiss watchmakers use lever escapements and we're no exception. It's simply proven to be the most reliable and energy efficient with centuries of tweaking and refinement. What sets us apart from others is our investment in building an in-house engineering team to develop proprietary escapements and secure our own IP, which only the upper echelon of watchmakers can achieve. We machine our own balance wheels and have developed our own silicon processes to ensure that this next generation material meshes well with more traditional metals and jewels within the movements. Our "secret sauce" at Horage is the true understanding and development of these processes, which is rare for a small independent brand.

Our most recent tourbillon piece, Lensman 1, has an oversized cyclops lens over the flying tourbillon at 6 o’clock, providing a more detailed view of the titanium cage and full silicon escapement that rotates with the balance wheel every 60 seconds. It clearly demonstrates the elements of the escapement in action and is truly a sight to behold.

We Want to Hear From You!

Sound off in the comments about additional topics of interest, so we can be sure to cover what you want to read in future articles. And please share this with friends and anyone interested in watchmaking, and let's keep the conversation going. Also, be sure to sign up for our newsletter (here) and keep an eye out for new products as we're always in the process of development. Check out journal entries as well (here) and a detailed section on performance watchmaking at Horage (here).

We'll talk again soon!

Erik Slaven

Now that you have a silicon hairspring and escapement. (What is the mainspring made of?) in the K2, what is the anti magnetic capability in Gauss? Is it also over 10.000?

I have recently researched all or most tourbillons on all major watchmaking pages as I am going to be a future lensman owner in April 😉😉 I have seen all major brand tourbillons and most expensive and most affordable according to my data from months of research the horage tourbillon is the 3rd lightest tourbillon on the market. I am going to name them in order of weight: 1- the non-flying tourbillon from the Bethune brand, it is all made of silicon, absolutely everything, including the balance wheel that has some white gold weights, weighs 0.18 grams, makes a full revolution every 30 seconds and beats at 5 hertz it has 2 barrels to control amplitude decay which add up to 120 hours of power reserve. 2- Parmigiani brand flying tourbillon weighs 0.25 grams and the tourbillon cage is made up of 64 pieces, the movement is automatic at 3 hertz and has a 48-hour reserve. 3- Horage with its flying tourbillon that weighs 0.29 grams, the cage made up of 34 parts, beating at 3.5 hertz with a single huge barrel and 120 hours of power reserve, although I still have some doubts as to how it will take the precision during the 5 days of power reserve by not having any specific technology to counteract the effects of loss of power reserve and prevent its amplitude from falling to a large extent...

In the photo you can see how 2 tourbillons seek maximum precision in a different way, one beats extremely fast at 5 hertz weighing very little with the lightest cage on the market, and another beats at a slow rate of 2.5 hertz but has a very heavy inertia due to its huge 16mm size tourbillon…

This was interesting thank you !

Extremely interesting info and methodology.

Great Post! You should follow it up with a post on George Daniels and the coaxial escapement, and compare and contrast it to the lever escapement! :)